Non Destructive Testing (NDT) LED Displays

Showing all 5 results

Non Destructive Testing (NDT) LED Displays

It’s understood that technologies used in the healthcare industry contribute to saving lives, but the best technologies also contribute to advancements across a broad spectrum of industries and governmental entities.

Combining Non Destructive Testing (NDT) LED Displays from Double Black Imaging with advanced testing technologies enhances safety efforts throughout those industries.

Double Black Imaging’s non destructive testing equipment delivers razor sharp images to meet the precise imaging requirements of the NDT industry.

NDT Methods

While hundreds of NDT methods and types of non destructive testing equipment have been developed to serve various industries, the most common types are:

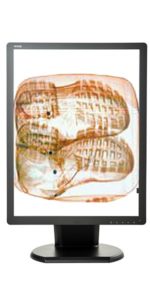

• Radiographic Testing: X-ray testing that can show internal features of an object.

• Penetrant Testing: Liquid testing of surfaces can find hidden cracks and fissures.

• Ultrasonic Testing: High-frequency sound waves can determine material thickness and composition.

• Magnetic Particle Testing: In testing ferromagnetic materials, magnetic testing can locate surface and subsurface flaws.

• Eddy Current Testing: Uses alternating electrical currents to detect flaws in conductive materials, such as metals.

Getting the most accurate readings from any of these methods of NDT is the most important component of protecting human safety.

Uses of NDT

There is a wide variety of uses for Non Destructive Testing (NDT) LED Displays across various industries. Some of the most important uses of NDT:

• Transportation: From roads and bridges, to railways and airplanes, every type of transportation industry and government entity relies on extensive use of non destructive testing equipment to ensure travelers are safe. Automobile parts must be tested. Train wheels and components, along with tracks, undergo repeated testing. Airplane engines, fuselages, and wings also undergo testing at government-designated intervals.

• Manufacturing: From tankers to toys, nearly every manufactured product must be tested to ensure consumer safety, along with all the components and machinery involved in the manufacturing process.

• Oil and Gas: Pipelines, ships, trucks, storage tanks – you name it, everything in the oil and gas industry undergoes constant testing to maintain integrity and to avoid catastrophic situations.

• Energy and Power: From poles to lines to generating facilities, NDT testing and equipment is a constant component of our electrical grid.

• Aerospace and Defense: Whether we send people into space or battle, lives depend on NDT testing to measure the quality of the equipment. Non destructive testing equipment guarantees precision in the tools and technology, and the sharpness is essential for safety and success.

How Double Black Imaging’s NDT Displays Help

Double Black Imaging offers NDT Displays that can enhance NDT testing in all these industries, whatever their preferred methods.

Our monochrome NDT LED displays are available in 2, 3 and 5 megapixel displays. All feature fixed front sensors for automatic gray level and luminance calibration.

Our color NDT displays are available in 2,3, 4, 6, 5 and 8 megapixel displays. All of these high bright color LED backlit LCDs feature fixed front sensors for automatic gray level and luminance calibration.

Double Black Imaging’s non destructive testing equipment displays come with CFS Client and Remote Administration DICOM Auto-Calibration Software, allowing all workstations to be configured for auto-calibration via the web.

Double Black Imaging can also provide installation, training, and support for your non destructive testing equipment and calibration software. Our technicians will install your workstations, install video card drivers and calibration software, and calibrate each unit. We also train your staff step by step as we conduct the installation and configuration process.

If you would like to learn more about the capabilities of Double Black Imaging’s NDT Displays or would like to request an on-site demonstration, contact the premier medical display company today.